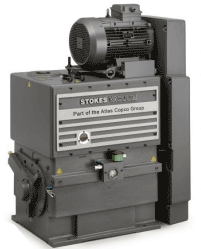

DRB 2000 Atlas Copco oil-free vacuum booster works wherever it is required to increase the pumping capacity and improve the vacuum. It has been designed to meet the highest requirements for modern vacuum production processes. This allows the compression of large volumetric gas flows in the range of accurate vacuum. Typical applications include those where rapid evacuation should be carried out in the shortest possible cycle time.

Booster vacuum pumps, also known as Roots vacuum pumps are generally used to increase the pumping speed of a system or with the goal of reaching a lower ultimate vacuum level. Booster pumps are used in a wide range of applications, most commonly used in the rough vacuum range, especially when high pumping speeds and low pressures are required, from atmosphere to 1×10-3 mbar. Due to the non contact rotational design of these pumps, they are able to run at higher speeds, offering increased pumping speeds for the backing pumps.

An added advantage is the lower energy consumption as compared to a single backing pump with the same pumping speed. DRB 2000 Atlas Copco oil-free vacuum booster is:

High Speed Packaging

Skin packaging for food preservation, inert environment in Pharmaceutical Industry and protection of sterile medical devices.

Drying & Freeze Drying

For product dehydration in food industry, Pharmaceutical, Dye and Chemical industry.

Vacuum Cooling

Rapid cooling with vacuum to enhance freshness and shelf life of your specific product like vegetables, fruit, flowers.

Industrial Vacuum

Multiple processes including altitude simulation, gas charging, catalytic convertors, leak testing, heat treatments.

Click here and compare DRB boosters by Atlas Copco.